ABOUT US

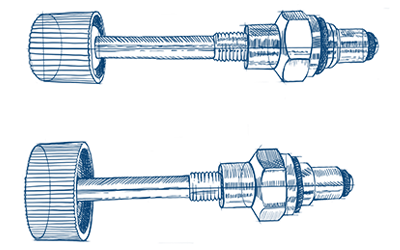

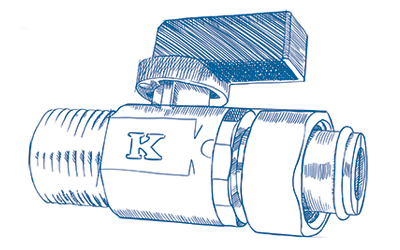

Established in 1974, Kramer Italia produces safety valves, automatic filling valves, air vents, motorised zone valves, gas taps, pressure reducers and various components for the heating, hydraulic, gas and solar sectors; the company also supports the major manufacturers of gas and biomass boilers by providing them with brass hydraulic units and related special items. The products for the OEM market are highly diversified to meet the needs of all customers.

SINCE

1974

KRAMER

WHAT WE DO

Over a surface of about 6000 square metres, Kramer is involved in designing, producing and selling standard items for heating, water, gas and solar systems, as well as customised solutions for gas and biomass boilers.

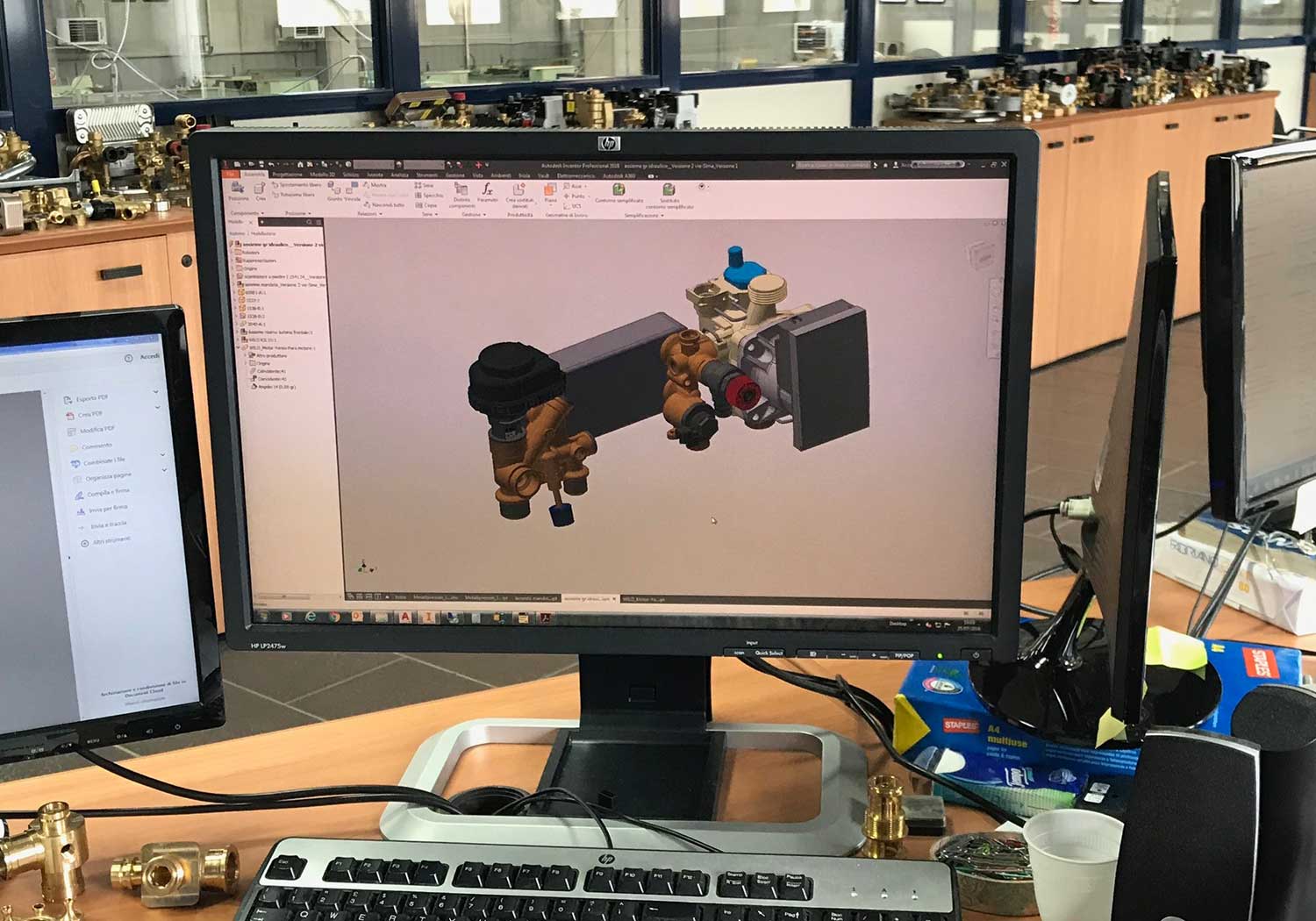

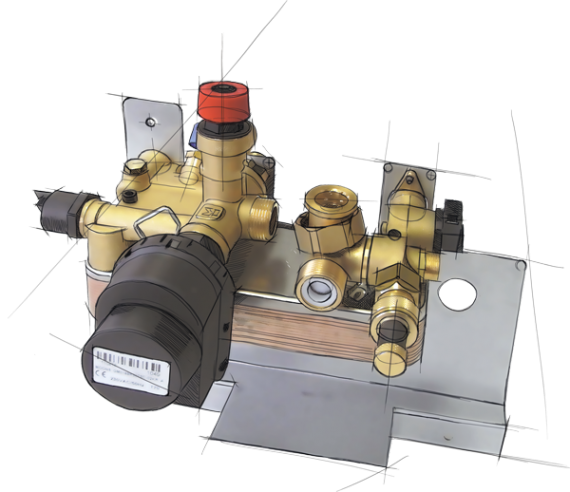

DESIGN AND DEVELOPMENT

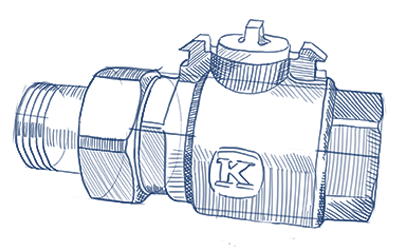

Kramer Italia offers the support needed to design and develop ad hoc solutions to manage the water flow in wall hung gas boilers and biomass boilers, as well as other components and/or different types of valves, ensuring a high level of customisation to tailor its products to the specific needs of each customer.

The technical office uses last generation software programmes, modern equipment and the company’s laboratory to carry out functioning and reliability tests on new products and relevant configurations.

The prototyping service allows to create functional prototypes within a reasonable time frame to perform tests as desired.

PRODUCTION

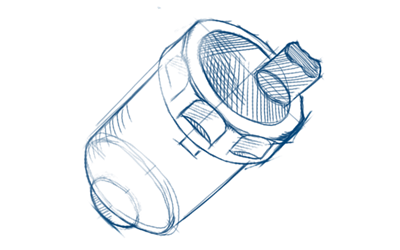

With the aim of meeting the needs for production efficiency and process cost reduction, with a steady quality control, Kramer Italia continually invests in new machining centres that are fully automated to carry out all mechanic operations on brass.

The manufactured parts move to the assembly department where they are mounted on automated lines or through manual operations, by integrating parts made of other metals, rubber and plastic which are custom designed and outsourced according to our specific needs.

Tightness tests on dedicated test benches and marking are the last steps of the assembly phase before packing and shipment.

CUTTING-EDGE TECHNOLOGIES

All equipment and machinery are highly technological and continuously optimised with the aim of improving quality and enhancing competitiveness, with an eye to the health of workers and the environment alike.

PRODUCT

CATALOGUE

Discover our range of products and download the catalogue and its product sections.

ABOUT US

Established in 1974, Kramer Italia produces safety valves, automatic filling valves, air vents, motorised zone valves, gas taps, pressure reducers and various components for the heating, hydraulic, gas and solar sectors; the company also supports the major manufacturers of gas and biomass boilers by providing them with brass hydraulic units and related special items. The products for the OEM market are highly diversified to meet the needs of all customers.

WHAT WE DO

Over a surface of about 6000 square metres, Kramer is involved in designing, producing and selling standard items for heating, water, gas and solar systems, as well as customised solutions for gas and biomass boilers.

DESIGN AND DEVELOPMENT

Kramer Italia offers the support needed to design and develop ad hoc solutions to manage the water flow in wall hung gas boilers and biomass boilers, as well as other components and/or different types of valves, ensuring a high level of customisation to tailor its products to the specific needs of each customer.

The technical office uses last generation software programmes, modern equipment and the company’s laboratory to carry out functioning and reliability tests on new products and relevant configurations.

The prototyping service allows to create functional prototypes within a reasonable time frame to perform tests as desired.

PRODUCTION

With the aim of meeting the needs for production efficiency and process cost reduction, with a steady quality control, Kramer Italia continually invests in new machining centres that are fully automated to carry out all mechanic operations on brass.

The manufactured parts move to the assembly department where they are mounted on automated lines or through manual operations, by integrating parts made of other metals, rubber and plastic which are custom designed and outsourced according to our specific needs.

Tightness tests on dedicated test benches and marking are the last steps of the assembly phase before packing and shipment.

CUTTING-EDGE TECHNOLOGIES

All equipment and machinery are highly technological and continuously optimised with the aim of improving quality and enhancing competitiveness, with an eye to the health of workers and the environment alike.

PRODUCT

CATALOGUE

Discover our range of products and download the catalogue and its product sections.

REGISTERED

OFFICE

Via Monte di Pietà 19

20121 Milano – Italia

Cod. Fisc. e Num. Reg. Imp. Milano 01755190152

ADMINISTRATIVE AND OPERATIVE HEADQUARTERS

Via Matteotti, 1

13864 Crevacuore (BI)

tel. +39 015.768832

Company subject to management and co-ordination activities of Tosi F.lli S.r.l.

REGISTERED OFFICE

Via Monte di Pietà 19

20121 Milano – Italia

Cod. Fisc. e Num. Reg. Imp. Milano 01755190152

ADMINISTRATIVE AND OPERATIVE HEADQUARTERS

Via Matteotti, 1 – 13864 Crevacuore (BI)

tel. +39 015.768832

Company subject to management and co-ordination activities of Tosi F.lli S.r.l.